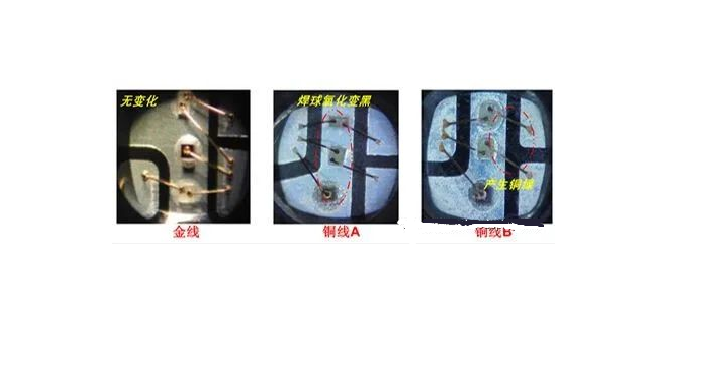

At present, LED display prices and brands on the market are mixed, and the price difference between display channels is very small, but the size of the company is different, and the operating costs are different. Some small companies have basically no after-sales warranty maintenance, and the corresponding quotation and large companies also have big differences. Many of the same model and brand products differ by hundreds or even thousands, so when choosing businesses, we must shop around and choose regular companies to buy, so that the quality and after-sales can be guaranteed. The price of the full-color LED display is composed of LED modules, power supplies, control systems, various connections, boxes, steel structures, distribution boxes, computers, lightning arrester, installation costs and other supporting equipment and services. The different prices of the lamp beads and driver chips used in the module are not the same, the prices of different brands of power supplies are also very different, and the thickness and material of the wire used are different (copper wire, aluminum wire). As far as luminous chips are concerned, they can be divided into imported materials and domestic materials. Each light chip is different, each has its advantages and disadvantages, the United States and Japan chip, because it has always mastered the core technology, in the context of similar monopoly, the United States, Japan chip prices are high. Taiwan and the mainland chip prices are relatively cheap, but its performance compared to the United States, Japan chip, there is still a certain gap. First-line brands, second-line brands, neutral packaging, different brand products use different component grades, and the price of finished products is very different. If the packaging method is different, the use of LED gold wire, silver wire, copper wire, alloy wire packaging, the corresponding price cost is different.

Gold wire package: high-end products, stable performance, high price. Oxidation resistance, anti-voltage, electrical conductivity, technical maturity and price have obvious advantages, of course, the price is higher.

Alloy wire package (also known as silver alloy wire) : a product that replaces traditional gold wire. The price is cheap, the price is lower than that of gold wire, the price is higher than that of copper wire, and the weldability is better when welding with silver plated support; In the old welding wire equipment, the application is not mature or need to install nitrogen protection to use. There is a certain degree of oxidation.

Silver wire packaging: Silver wire is better than copper wire storage (copper wire must be sealed, and the storage period is short, silver wire does not need to be sealed, the storage period can reach 6 to 12 months). The hardness is soft, and the machine parameters are not adjusted very much; The current price is lower than gold wire, higher than copper wire. Do not use gas protection when wiring; The pull of silver wire is not as strong as that of gold wire, but the time of light decay is better in silver than in gold, because silver does not absorb light.

Copper wire package: including single crystal copper wire and palladium-plated copper wire. The price of copper wire is low, and the various specifications of copper wire used in wire bonding have a cost of only 1/3-1/10 of gold wire, which has great application potential in reducing costs. The high stiffness of copper wire relative to gold wire makes it more suitable for small wire bonding. Copper wire is easy to be oxidized, the bonding process is unstable, and the physical parameters of copper wire such as hardness and yield strength are higher than those of gold and aluminum.

LED display price components LED electronic screen body: this can occupy more than 60% of the cost of the display, LED screen body is composed of display module, power supply, box, wiring power cord and so on. It is generally calculated according to how much per square meter. Control system: divided into synchronous control and asynchronous control two kinds. The main equipment includes video processor and control card. LED video processor is mainly to solve the problems of various video signal access, processing and display, and can complete the format conversion problem between many signal formats. The use of control cards is mainly based on the size of the LED electronic screen to determine the number. Generally speaking, the larger the area and the higher the density of the LED electronic screen, the more the number of receiving cards used. Control computer: The necessary equipment to control the LED electronic screen, and the configuration requirements are higher. Intelligent power distribution cabinet: equipped with power consumption of more than 10KW, it can provide voltage and power supply current for the stable operation of all components of LED electronic screen equipment, and effectively prevent failures such as LED electronic screen power supply source switch jumper box. Audio system: Let LED electronic screen synchronous video playback sound equipment, generally equipped with 1 power amplifier, 2 audio. Multi-function card: such as video capture card: installed in the computer, with the corresponding driver software, you can let the LED electronic screen play cable TV channel programs simultaneously, customer optional. Steel structure: used to fix the installation of LED electronic screen bracket, generally with steel frame structure, as well as aluminum plastic plate or stainless steel edge material. Freight, installation fees: depending on the distance of transport, including manual installation costs.